Our FlexBox and colourful flowers. Do they go together?

Yes they do!

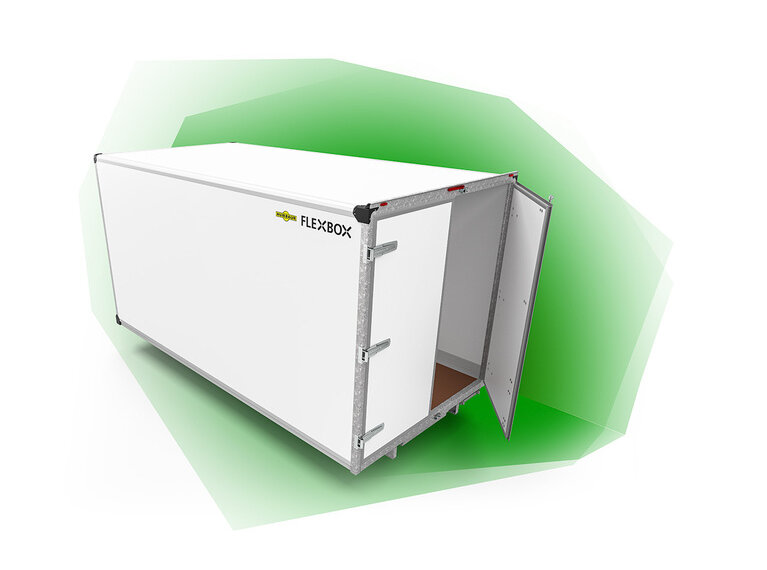

Very well, in fact. This is because the box body was especially designed to meet the requirements of the wholesale plant nursery trade. The entire vehicle is not only load capacity-optimised, but also equipped with a special transport safety system. Thanks to this, the typical CC containers can be secured quickly and easily. But that's not all. A parking heater warms the load compartment so that the floral cargo does not freeze in winter. And in the summer? Provide ventilation openings for sufficient fresh air. This means that plants such as chrysanthemums, cyclamen and poinsettias always arrive at their destination fresh and bright. But let's start from the beginning.

The colour green dominates. That is, if you are looking at the premises of Liebl Gartenbau- Vertriebs und Handels GmbH from the outside. Numerous delivery vehicles are parked in the yard. They are not only labelled with the company’s own logo with the red flower, but are also covered in advertising. But not just any advertising. Each vehicle supports a regional artist or the region itself. Charming. The region is Krumbach. Because this is where we are today to ask Bernd Liebl and his employees a few questions. He is the proud owner of a Humbaur FlexBox Dry – especially developed for the wholesale plant nursery trade.

Our box body in use – everyday life in the wholesale plant nursery trade

We may only be here for a few hours, but we’re keeping a very close eye on things. And we also quiz the staff. Because we not only want to know what a typical day in the nursery looks like, but also how our FlexBox performs on a day-to-day basis.

The vehicles are loaded in the evening. The trip starts the next morning. Early. Very early. Each box body has its own route and is provided with the corresponding load. When you push such a CC container for the first time, it is a little overwhelming. It's hard to see where you are going and it doesn’t necessarily roll where it should. Experienced employees even grab two of them, driving over the ramp and bringing the containers to the right place. The whole vehicle is loaded in no time at all. Two rows are loaded with three containers each, lengthways. This is followed by a crossways container and is completed by three lengthways containers. This means that the loading space is optimally utilised with 10 containers.

The vehicles are loaded in the evening. The trip starts the next morning. Early. Very early. Each box body has its own route and is provided with the corresponding load. When you push such a CC container for the first time, it is a little overwhelming. It's hard to see where you are going and it doesn’t necessarily roll where it should. Experienced employees even grab two of them, driving over the ramp and bringing the containers to the right place. The whole vehicle is loaded in no time at all. Two rows are loaded with three containers each, lengthways. This is followed by a crossways container and is completed by three lengthways containers. This means that the loading space is optimally utilised with 10 containers.

Comfortable driving – VW style

The base vehicle is a VW T6 with an AL-KO 13-inch chassis with air suspension. The 2.0 litre engine with 150 hp provides sufficient drive. However, with a length of 760 cm, a width of 210 cm and a height of 320 cm, it does take a little practice. Especially when reversing. No problem for Liebl employees, of course. The box body is the centrepiece. The FlexBox Dry is based on a weight-optimised GFRP structure. This allows the maximum load capacity to be utilised. The journey itself is pleasant. Comfortable. Once you sit in the vehicle, you quickly forget the actual dimensions. It can be driven confidently in road traffic and impresses with its typical VW operating and comfort elements. Once you arrive at your destination, additional rear indicators provide extra safety. Because you can see them even when the tailgate is open.

Making everyday life easier with smart details

That was our goal. And if we look at it this way, it has worked. The ramp is impressive. And heavy. It therefore needs four gas struts to open and close. Two of them only provide support from an opening angle of around 20°. What does that mean? It allows the ramp to be opened easily. Without great effort. The drive-up angle is particularly low thanks to the air suspension on the rear axle. This means that the CC containers can be easily pushed in. The locking system is not only adapted to the containers, but also to daily use. The load can be secured quickly and reliably. If the locking bars are not required, they can be stowed in the parking bracket at the rear right. Thanks to the 150 mm high scuff rails, the GRP inner wall is protected from impact and damage. Because this is unavoidable in everyday use. And the icing on the cake: the FlexBox also looks good.

Weight-optimised and cost-efficient development

But looks aren’t everything. At the end of the day, it’s all about hard facts. And here too, our box body impresses. This is because it is cost-efficient thanks to its thoroughly lightweight construction. This extends from the luggage compartment to the lightweight floor and the weight-optimised tailgate. The latter two rely on a core made from 100% recycled PET. This not only saves weight, but also protects the environment. Thanks to these optimisation measures, our FlexBox impresses with up to 150 kg more load capacity than comparable bodies. This means more can be loaded. This not only saves time, but also petrol and therefore money.

The day is drawing to a close. The employees of Liebl Gartenbau- Vertriebs und Handels GmbH want to enjoy their well-earned evening off. Around 30 people work here every day to ensure that processes run smoothly and deliveries are on time. Now in its 3rd generation, everyone pitches in. You can tell that real heart and soul has gone into it. Thanks to the work of Bernd Liebl and his team, not only plant nurseries and flower shops, but also DIY stores and food retailers are supplied with plants of all kinds. Our FlexBox Dry box body provides reliable support here. The many smart details make everyday work easier. Like the transport security system for CC containers. The weight-optimised and cost-efficient design was impressive. And because our FlexBox has proved so successful, it will soon be joining Bernd Liebl’s fleet. We couldn’t be happier and wish you a safe journey at all times.

Vehicle details at a glance

- Interior dimensions: 4,935 x 2,035 x 2,485 mm

- Overall vehicle dimensions: 7,600 x 2,100 x 3,200 mm

- FlexBox Dry on VW T6 chassis (traction unit) with 13-inch AL-KO chassis and air suspension, 2.0 litre engine, 150 hp

- Weight-optimised GRP superstructure for maximum load capacity

- Lightweight floor with anti-slip surface

- Lightweight ramp gate with sanded surface

- • Incl. auxiliary heating